Wastewater treatment - Textile and tanning sector

Los productos BEWAT eliminate the solids in suspension of the treated waters and help to discolor them. In addition, they favor biological processes and do not increase conductivity like inorganic or synthetic coagulants. In this way, water quality is improved, allowing compliance with discharge parameters and adequate water for reuse.

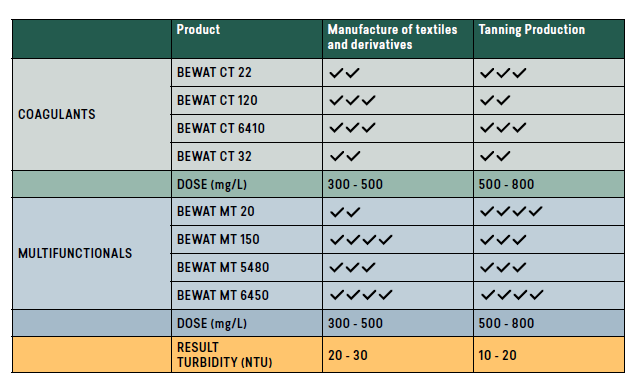

Tabla comparativa